In 1990, Asian Paints was a Rs 300 crore company. Today, it’s one of India’s most valuable consumer manufacturers; its market cap is about Rs 2.7 lakh crore. That’s growth, and an incredible one. Over the years, the company didn’t just sell more paint, but it built invisible walls around its business that kept competitors from entering this market at its level.

These are the unique advantages or ‘moats’ that protect a business from competition.

Asian Paints was started during the World War 2 period when almost all manufacturing was done in the west. Instead of relying on imported inputs or established distribution networks, the early founders developed their own local supply-chain, manufacturing and dealer relationships.

This early decision of building capabilities internally when external supply was unreliable would lay the foundation of a durable moat.

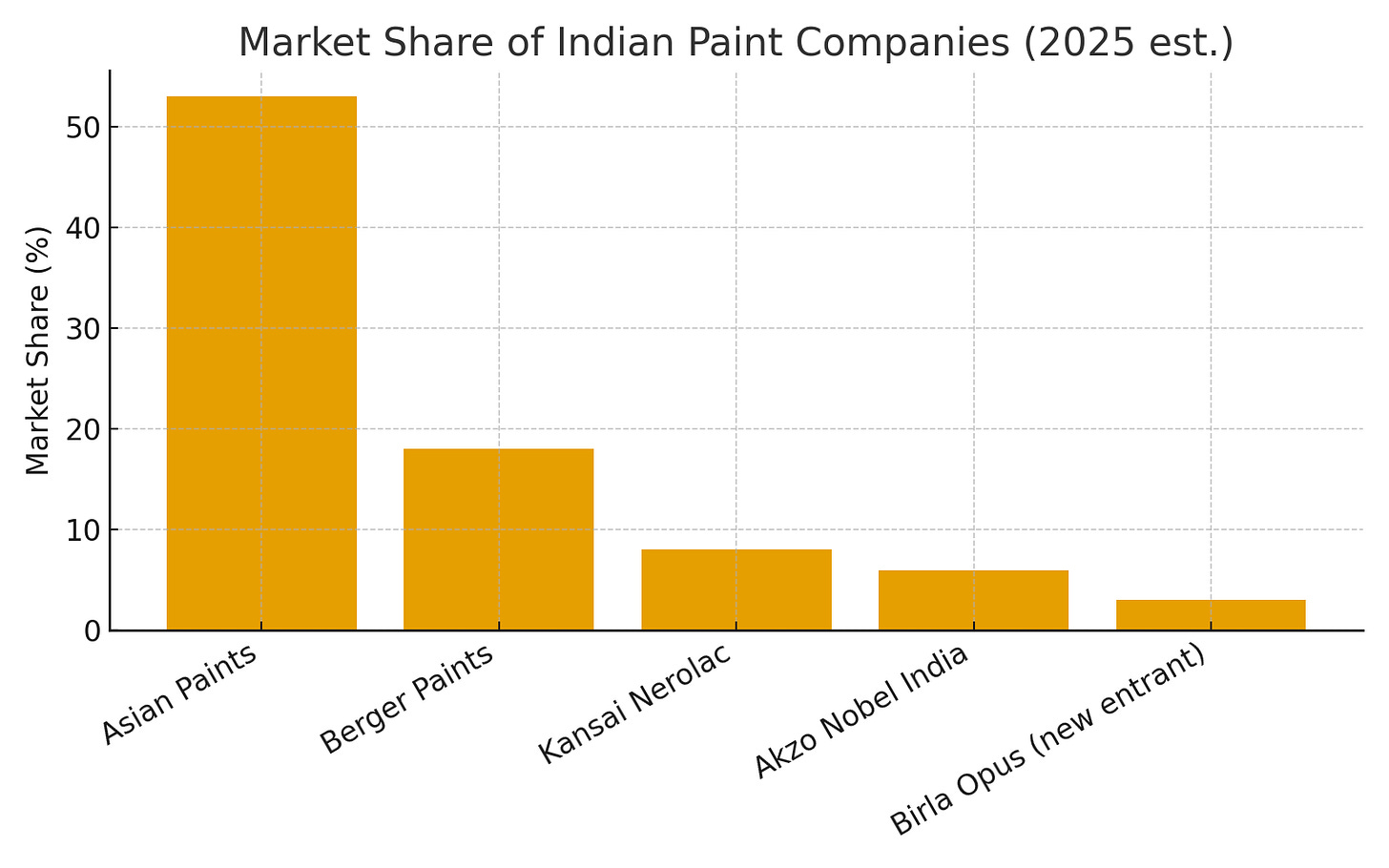

Asian Paints now controls more than half of India’s decorative paints market, with estimates placing its share at around 53% to 59%.

To put that in perspective, its share is larger than all its major competitors combined. But this dominance didn’t come from big-budget ads or celebrity endorsements. It came from decades of carefully designed systems, built around distribution, tech and data.

Defining the Moat

If someone is asked in the market about Asian Paints’ biggest strength, they might say its “brand.” But the real power lies even deeper.

The company’s edge comes from 2 forces:

a distribution network that reaches almost every corner of India,

and a data-driven forecasting system that keeps that network running smoothly.

Asian Paints has a network of over 1,60,000 dealers.

From small neighbourhood stores to large retailers, they are all connected through one of India’s most efficient delivery systems. Dealers rarely run out of stock, and orders are fulfilled within 24 hours in most regions. That’s the real game: it’s logistics.

Behind that logistics is the decade-long built data. Since the 1970s, Asian Paints has collected granular information on sales, colour preferences, seasonal demand, and even rainfall patterns.

In the 1970s, Asian Paints invested crores in a large mainframe computer, establishing a significant “data moat” that gave them a competitive edge.

Unlike most of its competitors, who used computers for basic functions like payroll, Asian Paints leveraged it to analyze decades of demand and supply records, dealer patterns, and geographic cycles.

This rich, historical dataset was instrumental in enabling the company to achieve superior forecasting, accurately predicting product sales across locations and seasons, and significantly improving its supply chain to offer service and availability that was beyond the reach of its competitors.

And this practice has continued till date.

Asian Paints vs Berger Paints: Same Product, Different Ways

To understand the strength of Asian Paints’ moat, it helps to look at a rival: Berger Paints, India’s second-largest player.

Both companies sell paint, but their strategies are entirely different.

Asian Paints holds about 53% to 59% of the Indian market, while Berger comes at around 18% to 20%. The gap between them isn’t about their size, but it’s about design.

Berger has built its brand through advertising and strong ties with contractors. Its campaigns are visible, colourful, and often trend-driven.

In contrast, Asian Paints’ focus has been less about advertising and marketing, it was more about building a deep, technology-led supply chain and ensuring that retailers never run dry even in extraordinary demand cycles.

A simple way to think about it: Berger focuses on what the customer wants to see. Asian Paints focuses on what the retailer needs to stock.

That’s why a customer walking into a local hardware shop is more likely to hear,

“Asian Paints is available anytime, do you want that instead?” or

“You can never go wrong with Asian Paints”

It’s a difference of philosophy. Asian Paints’ advertising is the confidence it pours into its retail network, which in turn fulfills the end-customer’s needs.

This strategy shows up in numbers too. Even as new competitors like Grasim’s Birla Opus enter the market, Asian Paints continues to deliver strong margins and fast turnover.

A Deccan Herald report in 2025 noted that while Asian Paints’ market share fell slightly to 52%, its profitability stayed resilient because of its tight cost control and un-hindered logistics.

How the Moat Was Built

The foundation of Asian Paints’ moat goes back to the 1970s.

Long before “data-driven” was a buzzword, the company developed its own ERP (Enterprise Resource Planning) system to integrate its factories, warehouses, and dealers into one synchronized network.

At a time when most Indian firms were doing manual accounting, Asian Paints was using computers to track paint cans.

Over time, this system evolved into a self-reinforcing loop:

more data → better forecasts → faster delivery → happier dealers → more sales → even more data.

This wheel became the company’s biggest strength. It didn’t just make operations efficient, it made them almost impossible to copy.

You can buy machines, hire people, even replicate colours. But you can’t instantly replicate decades of data, dealer trust, and institutional discipline.

Even the company’s culture supports the moat: dealers get paid on time and inventory moves quickly. The result: consistent returns, low debt, and one of the best working-capital cycles in Indian manufacturing.

The Hidden Moats

Beneath all the technology and logistics lies something softer but equally powerful, which is trust. In India’s paint market, the real decision-maker is often not the end customer, but the small retailer or local contractor who recommends which brand to use.

Over decades, Asian Paints has built relationships with these local players through reliability, timely deliveries, and financial support.

Another quiet moat is its frugality. Despite its size, Asian Paints keeps tight control over costs. It doesn’t get into aggressive price wars.

As reported by The New Indian Express in 2025, the company publicly stated it would not slash prices to fight new entrants: choosing to “protect margins through efficiency rather than undercutting.”

The Industry Landscape

India’s paint industry itself is growing rapidly. According to Mordor Intelligence, the market is projected to reach about $10.5 billion (Rs 90,000+ crore) in 2025 and nearly $16.4 billion (Rs 1.4 lakh crore) by 2030, growing around 9.4% annually.

This growth brings opportunity as well as competition. New players like Birla Opus, JSW Paints, and Nippon Paint are investing heavily in capacity and brand-building.

Even with these challenges, Asian Paints continues to lead the sector by a wide margin. The businesses competitors can develop and master the colour shades, but they will have a long and tough journey to build the decade-old systems. That’s what makes Asian Paints’ moat so durable.

For over 80 years, Asian Paints’ moat lies in one dealer, one can, and one dataset at a time.

The kind of ‘distribution+data’ moat that Asian Paints has built isn’t unique to paints alone. You can see hints of it in Hindustan Unilever’s retail reach, ITC’s supply network, TCS’s technology moat, and even Varun Beverages’ cold-chain process.

Each has its own version of the same principle: building invisible walls so high and sturdy that competition struggles to climb up.

In the next editions of this series, we’ll dive into more such remarkable moats.

Exciting content, helps to know about the companies and their business model

I loved this "Berger focuses on what the customer wants to see. Asian Paints focuses on what the retailer needs to stock."

Concise and well written